Fix a Tesla Cybertruck with Glue? How Structural Adhesives Repair Cars, Trucks, and SUVs

Structural adhesives for auto repair have been around for much longer than you think and how many important vehicle assemblies are manufactured.

While it may seem wild that something like the Tesla Cybertruck and other modern vehicles use glue to not only repair damaged frame castings, but adhesives are also used to manufacture this heavy pickup truck. It’s not the only vehicle on the road today that uses structural adhesives in both manufacturing and repair, but gluing structural parts like your unibody frame isn’t a new technique, either. This is especially true for a frame or part that may use incompatible materials or composites to create it.

Before we go Further

As an independent automotive media source, Carbage.Online relies on a combination of sources to pay for staff, buying equipment for testing, travel, and more. While turning off your ad blocker is an immense help, an even greater one is donating to our Patreon. For as little as a $1 per month, you’ll gain access to exclusive stories, opinion pieces, and other features not found here or on our YouTube channel. One of the features you gain access to at this level are comments on these stories that go live on the site. Support our independent work, reduce our need for ads, and let’s all build this site into an amazing collection of automotive tech and motorsports.

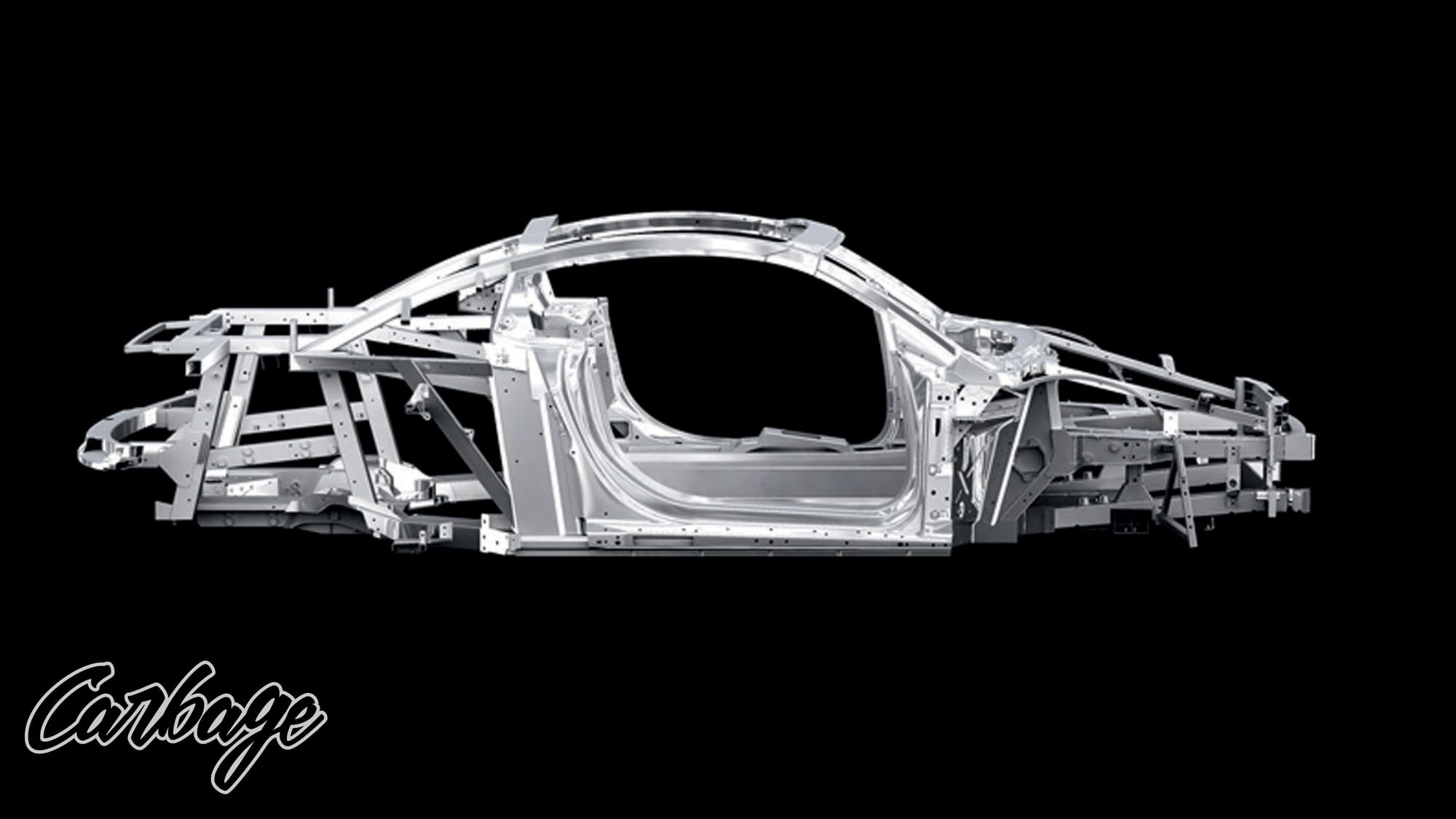

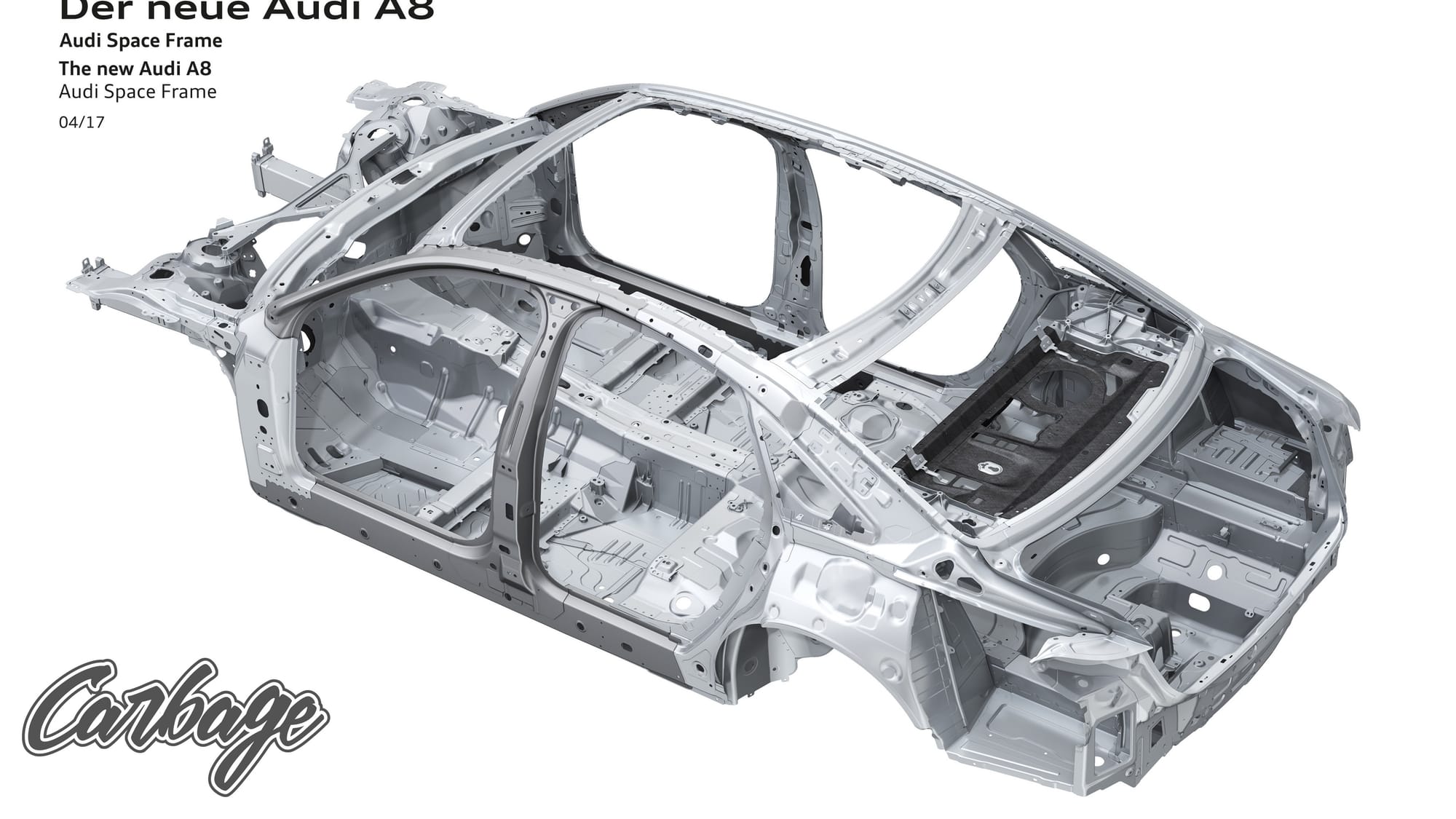

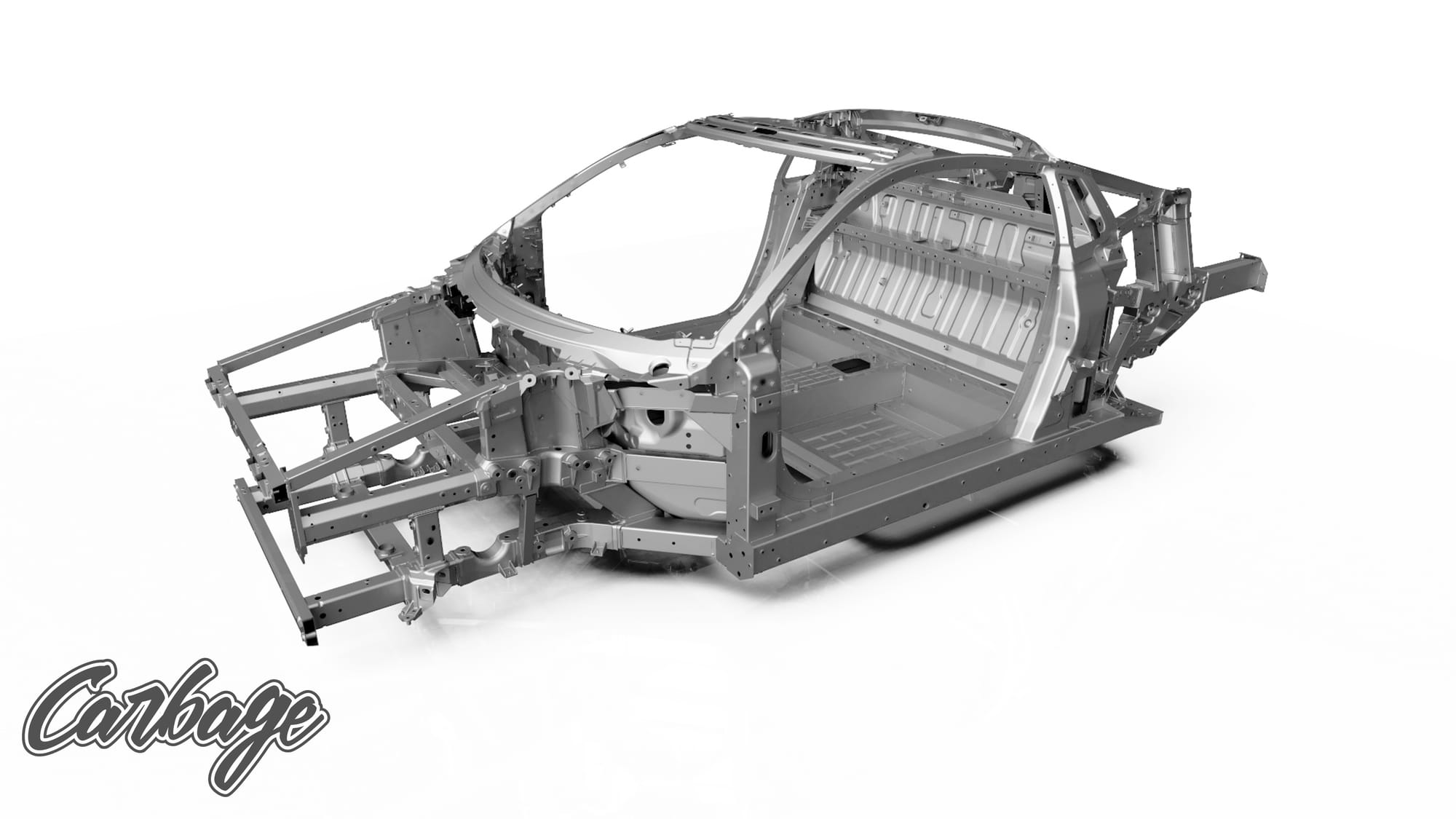

The Cybertruck isn’t the First or Only Vehicle with an Aluminum Structure

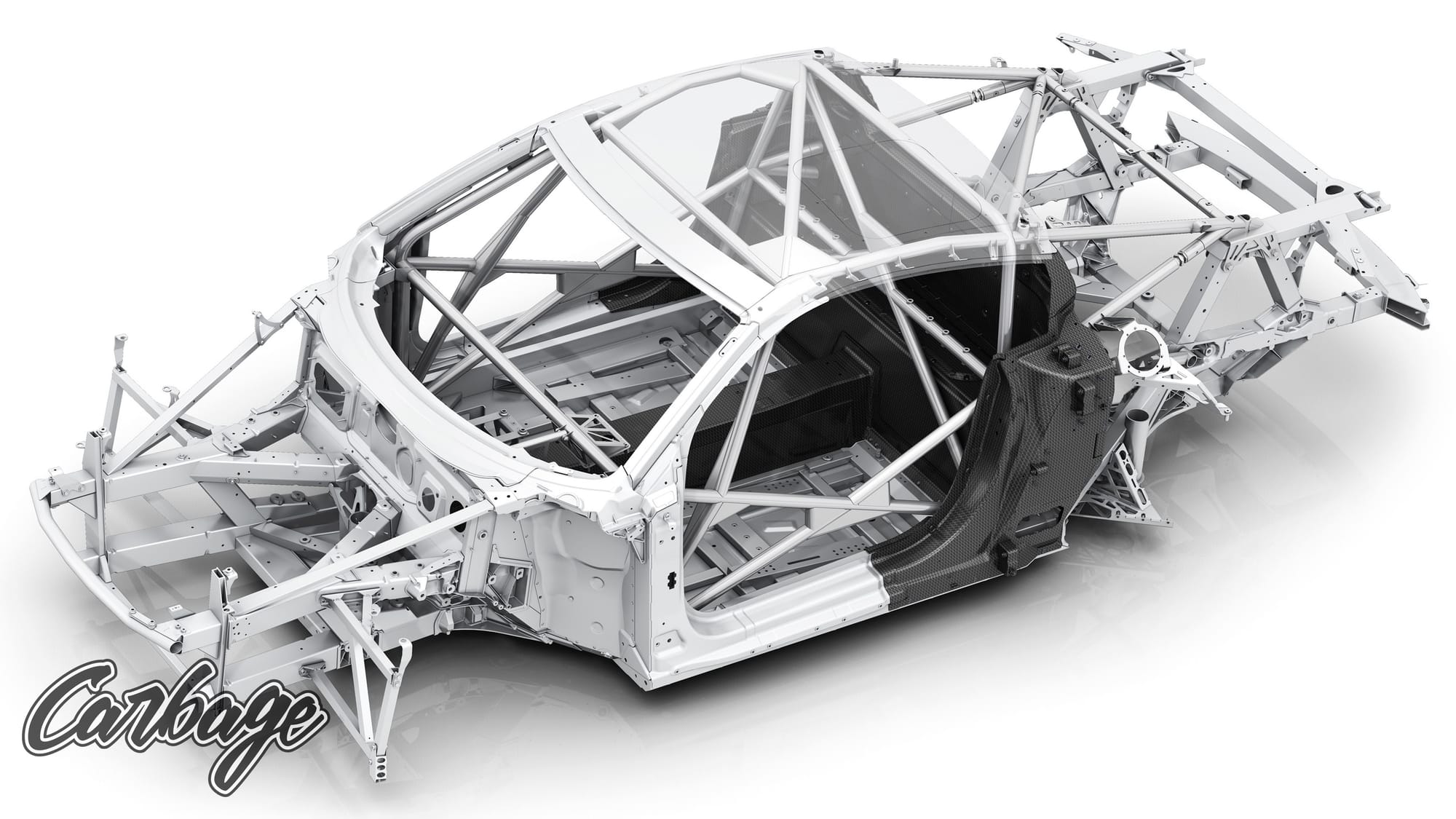

While there have been a few one-offs and technical demonstrations of aluminum frames, the credit for the first ever mass-market aluminum structural unibody goes to the 1994 Audi A8. The US didn’t receive it until 1996, but the all-aluminum unibody was part of Volkswagen Groups D2 platform and marketed as the “Audi Space Frame.” Despite the use of aluminum, the A8 was offered in a standard wheelbase 113.5-inch and long wheelbase (LWB) 118.5-inch versions, of which the latter gave an additional 5 inches of legroom for the rear passengers. This same unibody technology was also applied to the 1996 S8, the high-performance version of the A8, and even saw use in the R8 LMS racecar.

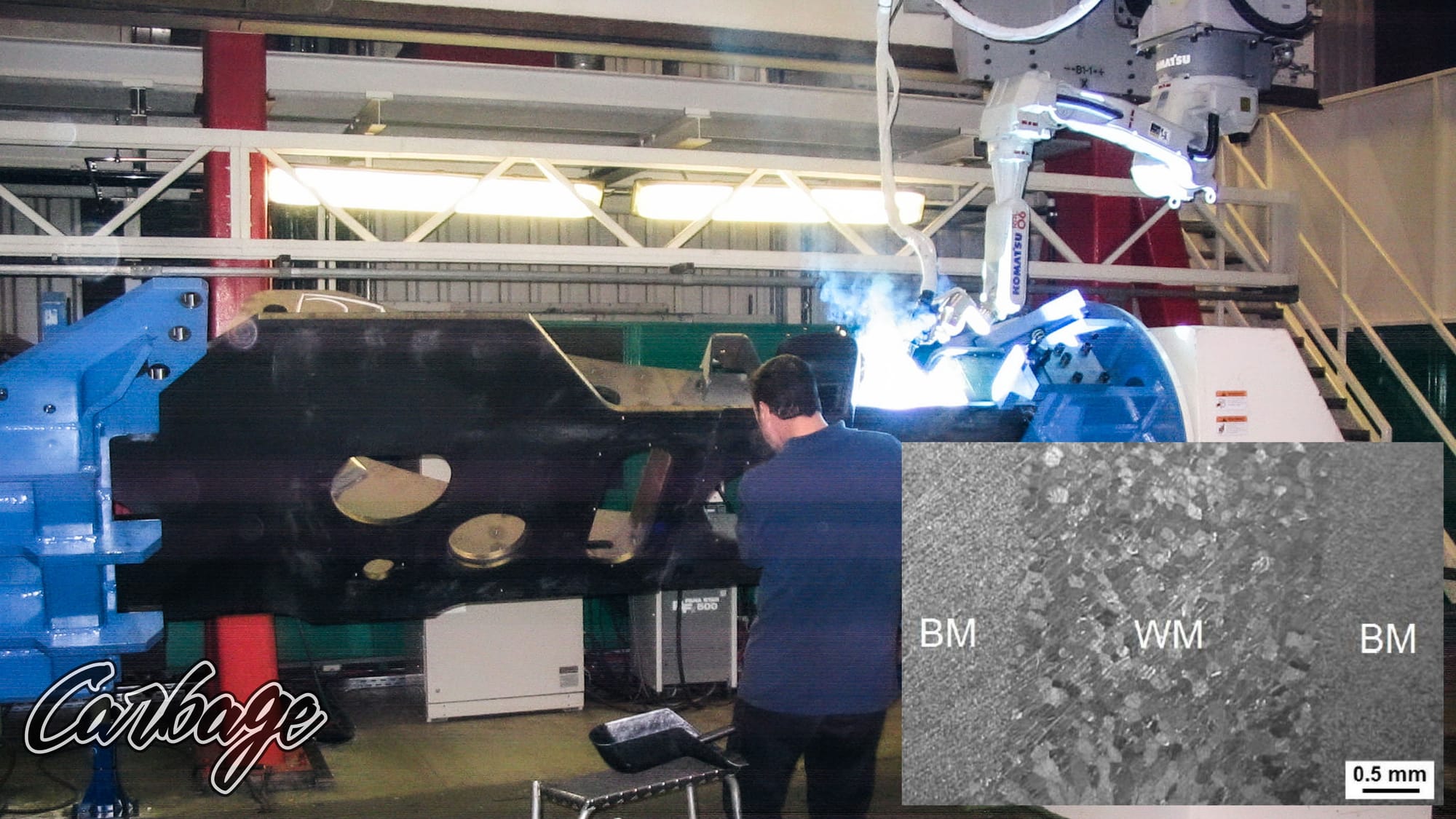

Yes, You Can Weld Aluminum, but There’s a Catch

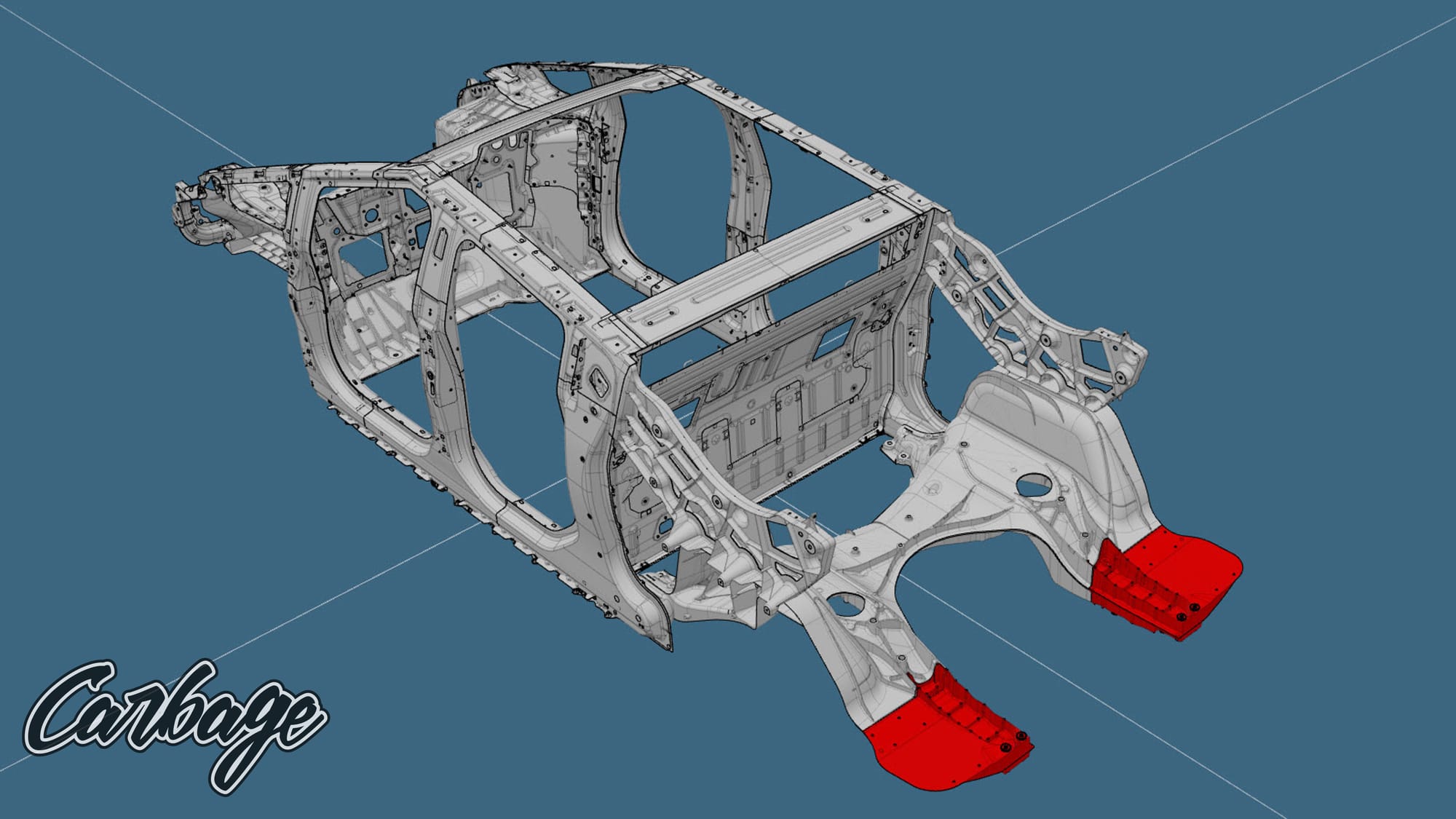

Before we get into the “gluing,” you probably have a question. “Why wouldn’t you want to weld aluminum alloy wheels and structures together in the first place?” While that might seem like an obvious procedure, welding aluminum has issues in the mass manufacturing world of building automobiles and it’s not the complexity of having a robot weld parts in various lines and contortions. It’s also not that evident when looking at a finished welded aluminum part, either. At the atomic level, welding and the heat generated creates hardened metal. While that sounds like a great idea, hardened metals can be more brittle and break easier than the metal you started with. This can be especially true with aluminum and, in something as important as your vehicles frame, you don’t want that happening as that’s the only thing holding important parts like the body, suspension, brakes, and other critical parts to your car.

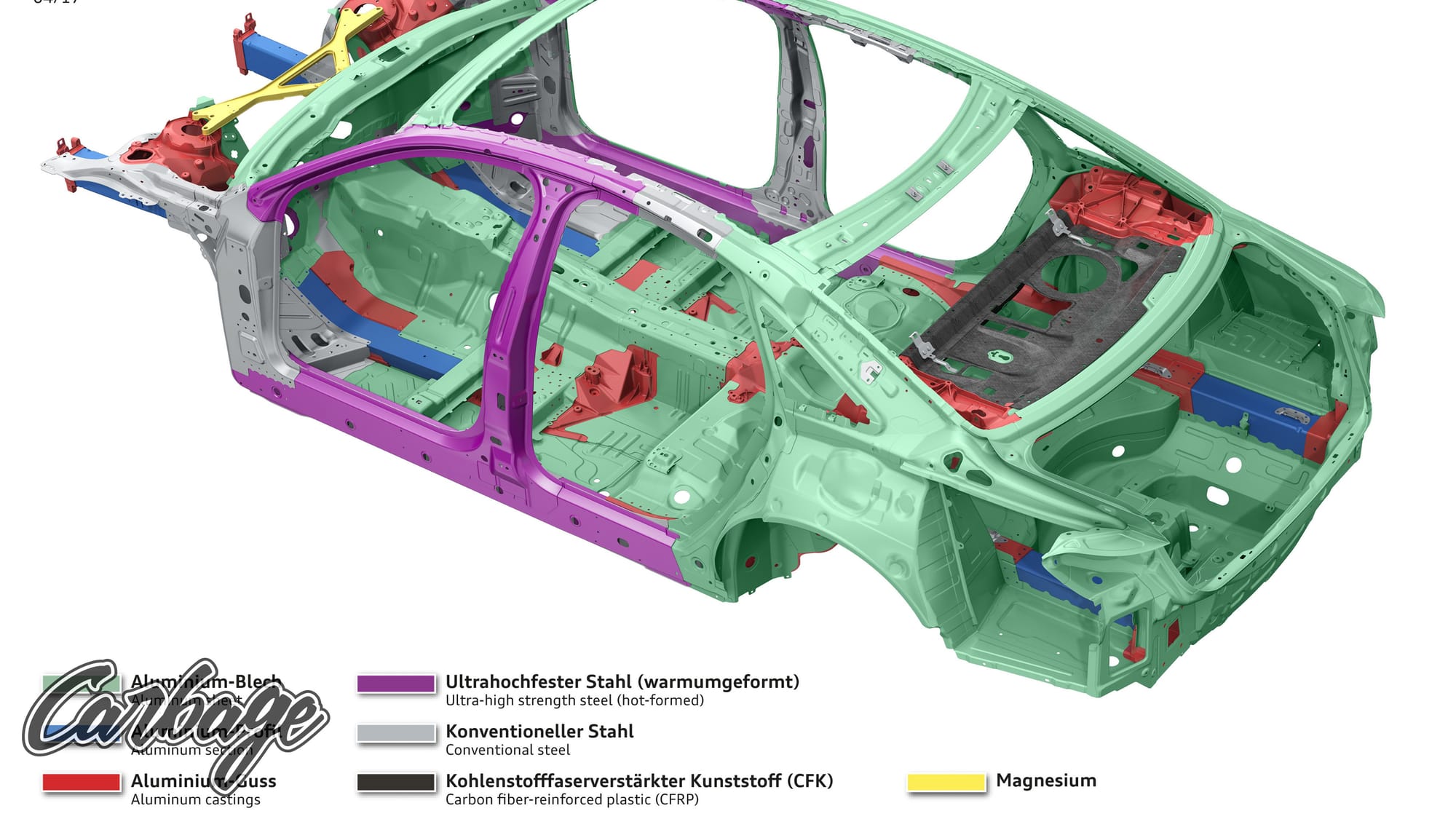

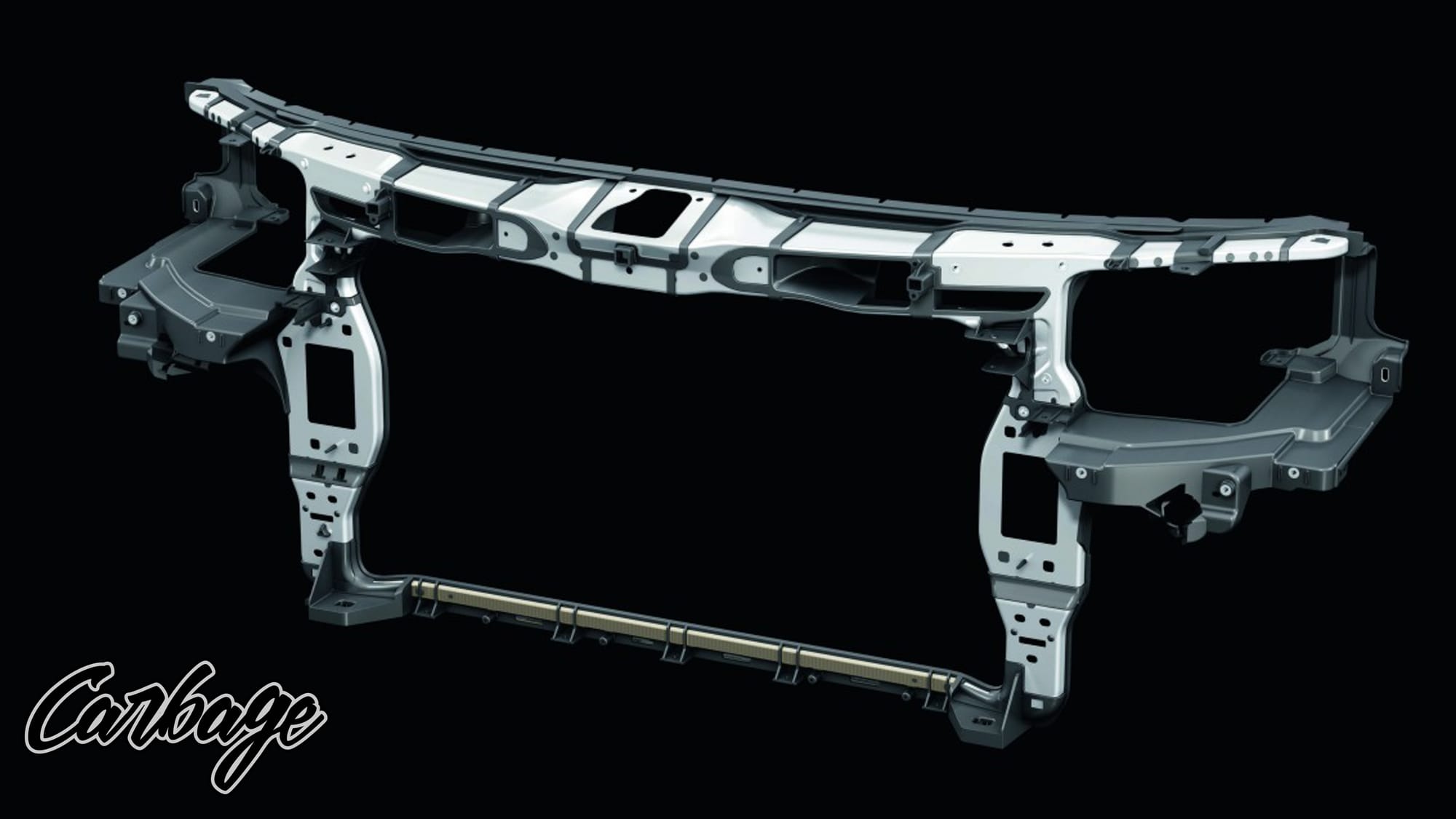

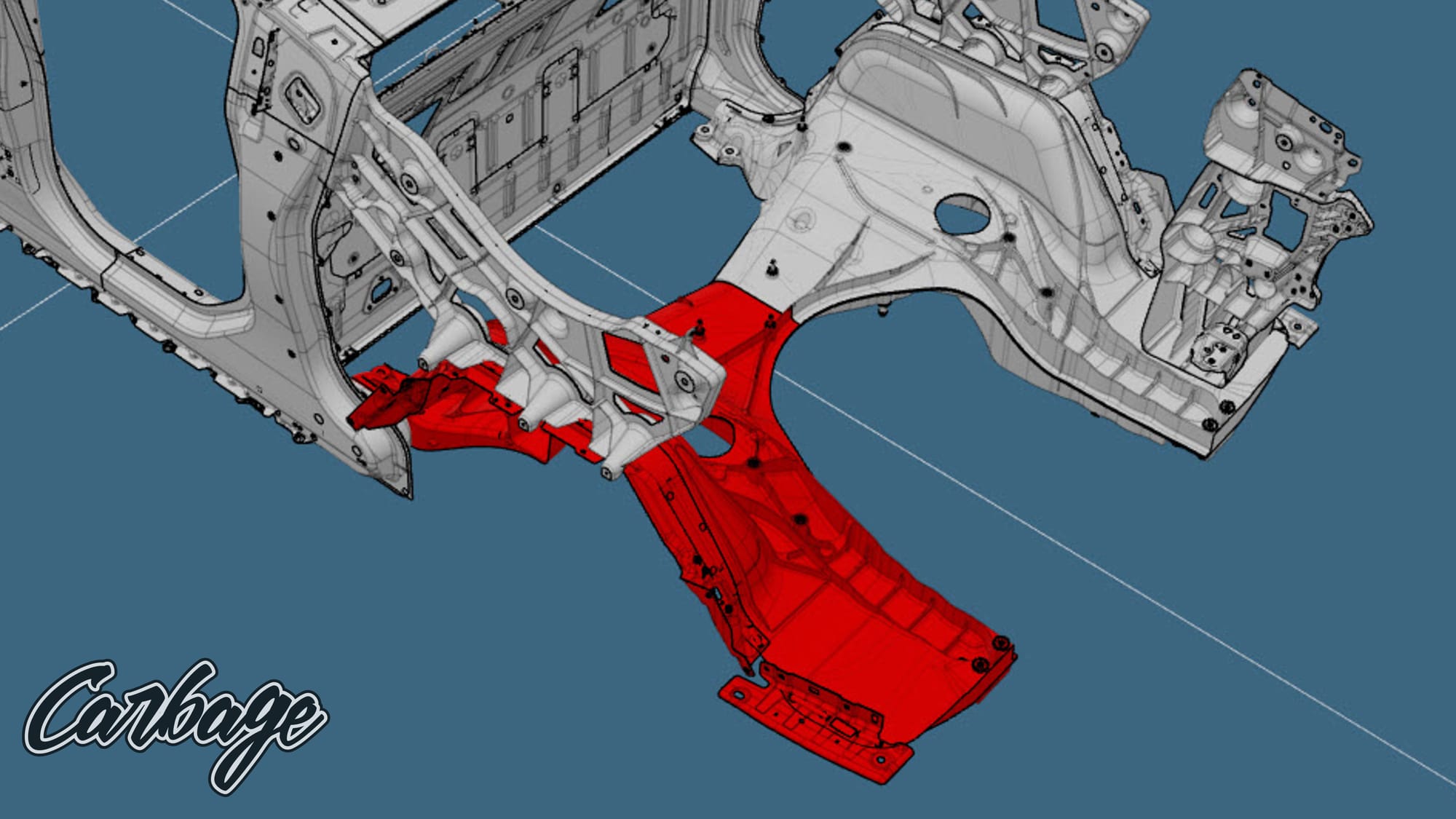

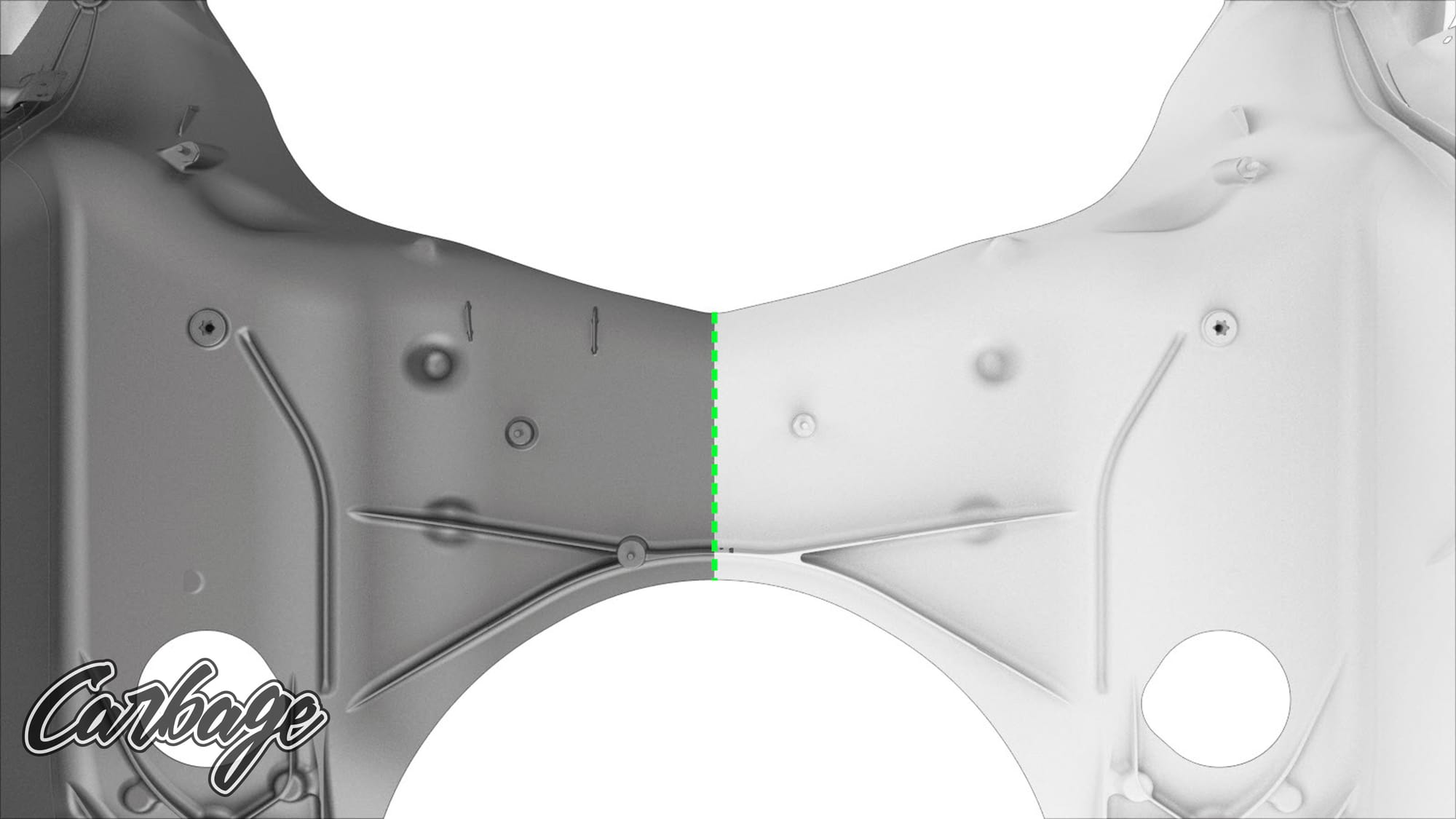

There’s an additional issue, too. While you might want aluminum in some places, you might want or need steel, a different and un-weldable alloy of aluminum, or even a composite like carbon fiber as part of the unibody structure. Even that first A8 and the R8 both didn’t completely use aluminum in key structures of their chassis. What do you do then? You could rivet those metals together, but that doesn’t work so well on composites and adds complexity and costs to the manufacturing process. Could bolt them together and that might be better for composites as you can add a threaded insert to it, but that again adds complexity and cost to the assembly. What exactly are you left with? Adhesives.

What is a Structural Adhesive?

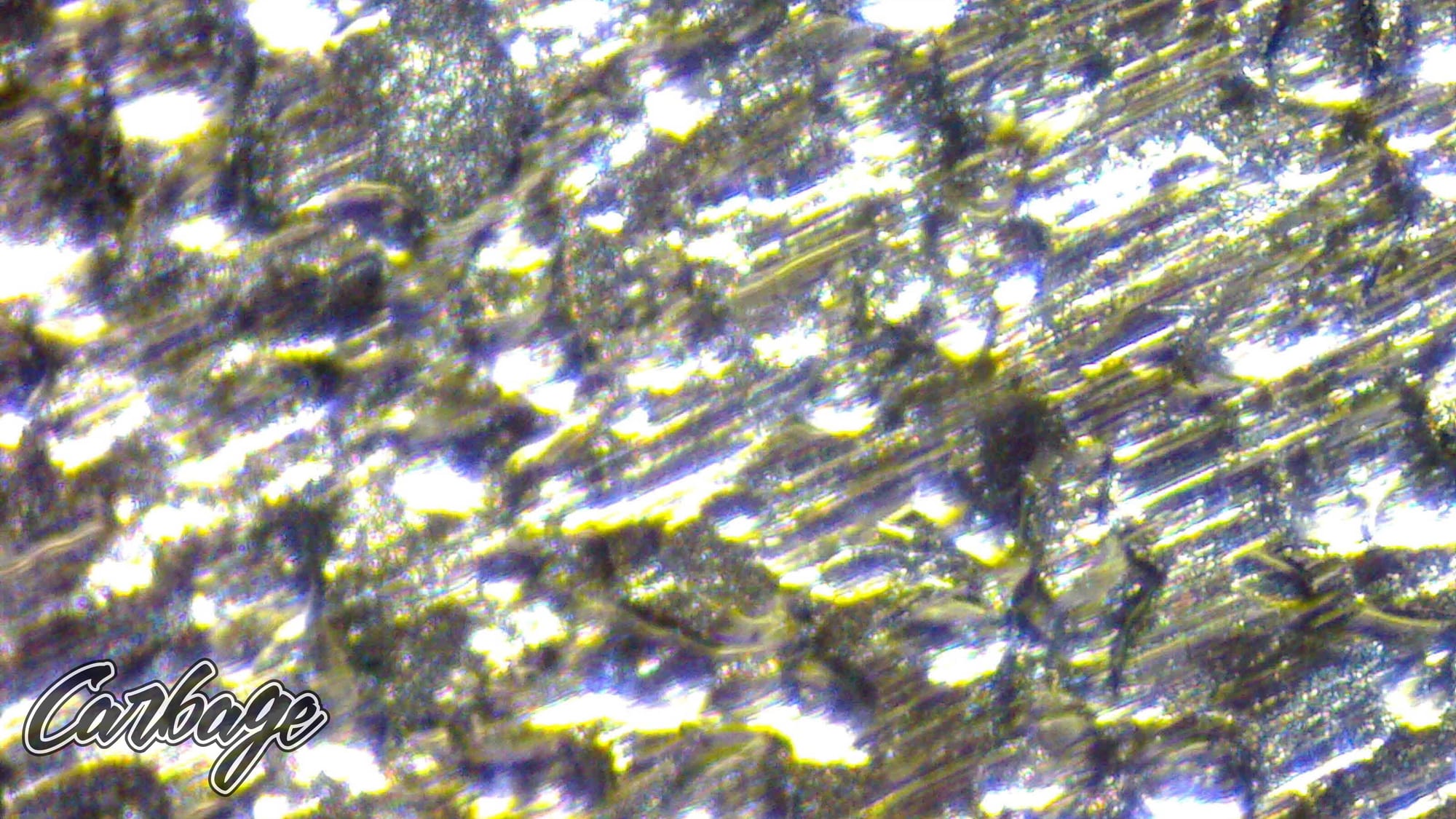

Before you start worrying about the glue coming apart because the first thing you think of are super glues and the PVA glues from your childhood, we’re talking about a whole other level of adhesives. At the basic level, they work and achieve the same thing: bonding two materials together. What exactly does that mean, though. The surface of a material you’re looking at isn’t as smooth as it feels. From the microscopic to even the atomic and sub-atomic levels, the surface is jagged and grooved. A metal or plastic may feel smooth after a polish or sanding, but all you’ve done is worn away or burnished those edges down to be so small that your fingers can’t tell anymore. Adhesives work with those small grooves and edges and mechanically lock in and bond to that surface and the other surface you’re trying to glue together.

While your favorite school glue will hold paper together and you can assemble some amazing models together with cyanoacrylate (CA aka super) glues, these alone won’t provide enough bonding, or the dried glue will simply just not be strong enough for load bearing. This is the difference between those glues and the structural adhesive used to bond aluminum and other structures within your car, truck, or SUV. Many companies utilize many different chemicals like polyurethanes, cyanoacrylates, phenolics and many others to create these super bonds and nearly all come as a two-part system that is mixed only when you’re ready to tie the two materials together. Some structural adhesives will cure over time while others require specific heat, humidity, and even exposure to ultraviolet light—it all depends on what chemicals were used to create them.

The JerryRigEverything Cybertruck Repair

What was great about Zach Nelson, better known as JerryRigEverything, getting access to document the repair to his Tesla Cybertruck frame was introducing his audience to a process that is common within the automotive repair industry, but is otherwise unknown to the average person. It opens people’s eyes to just how amazing engineers are in our world that help create our vehicles. It also shows that auto repair is more than just turning wrenches and is a huge world of STEM—Science, Technology, Engineering, and Mathmatics.

It was a huge example of how strong structural adhesives are that are used to repair our vehicles. While rivets are used during the repair process, those rivets are not structurally sound enough to support the loads and impacts that frame might see, they are used to secure the two pieces of metal together as the adhesive cures. Proof of that was in the test that Zach did that didn’t use any rivets and only the adhesive.

Utilizing the adhesive process to install the repair structures on his Cybertruck, Zach made a two-piece shackle using a 2.5-inch diameter round stock of aluminum and the two-part Parker Fusor 2098 adhesive called out by Tesla to bond its repair structures together. He then put that between two D-rings before hoisting his Cybertruck into the air via a crane. I’ll let you watch the video as the entire process is fascinating to watch, but I’ll just say I wasn’t surprised by the result.

Comments ()