What is an Alloy Wheel and How are They Made?

Alloy wheels have been standard equipment for modern cars for decades, but what exactly are they and are alloys different from aluminum wheels?

Whenever you look over a specification and equipment sheet of that next new or used car you’re looking at buying, you’ll find a callout for “alloy wheels.” If you’re not dedicated to the automotive industry, you probably wonder just what the heck are they? The look like aluminum wheels, but they are always listed as “alloy.” Are they really the same or are they different? If you’re wondering about that and how those wheels are made, then this is the tech dive for you.

Before we Continue

As an independent automotive media source, Carbage.Online relies on a combination of sources to pay for staff, buying equipment for testing, travel, and more. While turning off your ad blocker is an immense help, an even greater one is donating to our Patreon. For as little as a $1 per month, you’ll gain access to exclusive stories, opinion pieces, and other features not found here or on our YouTube channel. One of the features you gain access to at this level are comments on these stories that go live on the site. Support our independent work, reduce our need for ads, and let’s all build this site into an amazing collection of automotive tech and motorsports.

Alloy Wheels, Aluminum Wheels, What Gives?

When you see the term “alloy wheels,” generally speaking these are aluminum wheels on most cars, trucks, or SUVs you’re shopping for. An alloy is simply a mixture of metals to create a better material by taking advantage of the positive properties (usually) of the metals used. Alloy metal isn’t limited to just aluminum, though, and there are other alloys used throughout your vehicle like the stainless steel used for the exhaust piping, titanium where maximum lightness is required, and bronze bushings used in a variety of places where slow rotation and movement don’t require ball bearings.

There was another alloy metal once used in the production of car wheels and that was magnesium—commonly referred to as “mag wheels.” Magnesium isn’t used much in the wheel market due to the cost of forging and the cost of this lightweight metal alloy, especially when compared to aluminum. Older mag wheels (and magnesium in general) were also easy to catch fire, but those issues have been solved for many decades. Solved to the point to be used as engine blocks, brake calipers, and even in the cabin of the aircraft you take to fly across country. There’s even magnesium parts that make up your phone that you’re probably reading this story from. High-performance wheel maker, Dymag, were once known for their magnesium wheels on Lola and Reynard Indy race cars and various racing motorcycles but have recently moved on to carbon and carbon hybrid wheels.

What is a Cast Alloy Wheel?

There are three processes used in the manufacturing of alloy wheels. The first is the simplest and typically the cheapest is casting. If you’ve ever made a shaped cookie or cake, you’re sort of familiar with the process. You melt aluminum down to its viscous state and simply pour that molten metal alloy into a shaped mold. Once sufficiently cooled, a manufacturer like Enkei Wheels will take that formed wheel and machine away flash—the metal that happened to ooze out of the mold—add features like logos and undercuts, face and set the backspacing (or offset, depending on who you talk to) and drill out the lug pattern. After this, the wheel is sent to be powder coated or painted. Sometimes, certain wheel designers will option to further machine features into the wheels and polish these areas to create a polished aluminum finish to contrast against the wheel color. OEMs like to do this quite often with “black and machined” wheels.

What is a Flow Formed Alloy Wheel?

The next process is relatively new in terms of manufacturing but is a mixture of casting and forging to a degree. This is known as flow forming and it starts with a cast molded into the general shape of the wheel and the fully formed face (minus the machining work). A forming tool is pressed into the area known as the barrel of the wheel and forms it out using enormous amounts of pressure and many passes to not stress the material while forming. This forming process draws out the aluminum and creates a more rigid form without making it harder. A harder metal is usually more brittle and easily breaks apart, something you don’t want from the part of your car dealing with potholes and other road imperfections daily. The reason flow forming makes a more rigid barrel is it takes the chaotic looking grains you’ll see at the microscopic level from the cast metal and forms them into longer, conforming grains. Once the barrel is formed, the wheel is finished just as a cast wheel is.

What is a Forged Alloy Wheel?

Finally, we come to the strongest and most rigid manufacturing process for your wheels: forging. This process is as old and relatively unchanged since the bronze and steel ages. Most of the change comes in how we smash these alloys to create the strong, lightweight wheels race teams clamor for. Rather than rely on a strong person slamming a hammer down onto the metal, machines now do the hammering. But the result is still the same, forging not only forms the billet into the shape of the wheel but also takes those microscopic chaotic grains that make up the alloy and lengthens them out and conforms them to the same direction. Forging makes an alloy wheel strong enough that less material is needed when compared to casting and flow forming and that results in a much lighter wheel than either.

Once the forging process is complete, these wheels are finished with machining work—including undercuts and further material removal for further weight savings—and then sent to be powder coated or painted. Again, some additional beauty work can be performed after powder coat or paint to bring about the bare aluminum to be polished and cleared over.

The one disadvantage to forging is the cost. Where a set of cast aluminum wheels might sell for a few hundred dollars—sometimes less than $1,000 for a set of four—a single forged wheel can cost a $900 to $1,500 dollars apiece for something you can get from Volk Racing, and high-end, super lightweight forged centerlock racing wheels can range from $9,000 to as much as $20,000 for a set.

Are Alloy Wheels Worth It?

When it comes to wheels, very few steel wheels match the stunning looks of even some OEM cast alloy wheels. You also can’t beat the weight savings an alloy wheel has over steel and that means a reduction in both rotational mass and unsprung weight for maximum performance from your car, if you care about such a thing. There is an argument that the weight of an alloy wheel will allow for better mileage over a steel wheel, as well, though the cost savings in gas or diesel will take a long time to recuperate from your alloy wheel purchase. A steel wheel will be stronger than a cast wheel, but it’s hard to beat the strength to weight of a proper flow formed or forged aluminum wheel. Even many off-road racing teams are utilizing flow formed and forged aluminum wheels while smashing into rocks and boulders in Ultra4 and Trophy Truck racing. If alloy wheels were a significant weak point, these teams wouldn’t bother.

If your daily driver comes with alloys from the factory or is equipped with them when you purchase it used, changing over to steel wheels won’t offer any benefits and may (may) be a deficit in your pocketbook in both the cost of buying a set and losing out in fuel economy, however small that might be. Alloy wheels also deal with salt and other forms of corrosion much better than steel wheels, especially newer alloys made with modern materials.

If you’re looking to upgrade, you’ll want to consider what you’re willing to trade off and your budget. If you can splurge on a set of forged aluminum wheels, go for it—cost is the only downside here. If your car already has alloy wheels and you’re looking to shave time off your lap or quarter-mile ETs, you’re better off starting with a set of tires as your modification here. There are multiple improvements that will immediately be felt and shown on the timing sheets as better rubber on the road will lead to increased forward grip, lateral grip around corners, and more bite when hitting the brakes. After that, then maybe think about your wheels, but there might still be better choices before going with a set of forged alloys, especially when considering the cost of those wheels.

But, man, it’s hard to argue against the change in looks a set of alloys can bring to a car, truck or SUV. If that’s your focus, find a wheel that fits both your vehicle, budget and taste. If you happen to be slightly unlucky, your wheel choice might be limited due to fitment, bolt pattern, or both. We’ll speak about spacers and bolt pattern converters in another story, but when properly installed AND maintained, these items are safe. It is best to find a wheel that fits and to not rely on those items, especially if the spacer drastically changes the wheel offset/backspacing. If you are someone who just wants to slap something on and forget it, spacers and bolt pattern converters are especially not for you.

Alloy Wheels are a Great Choice

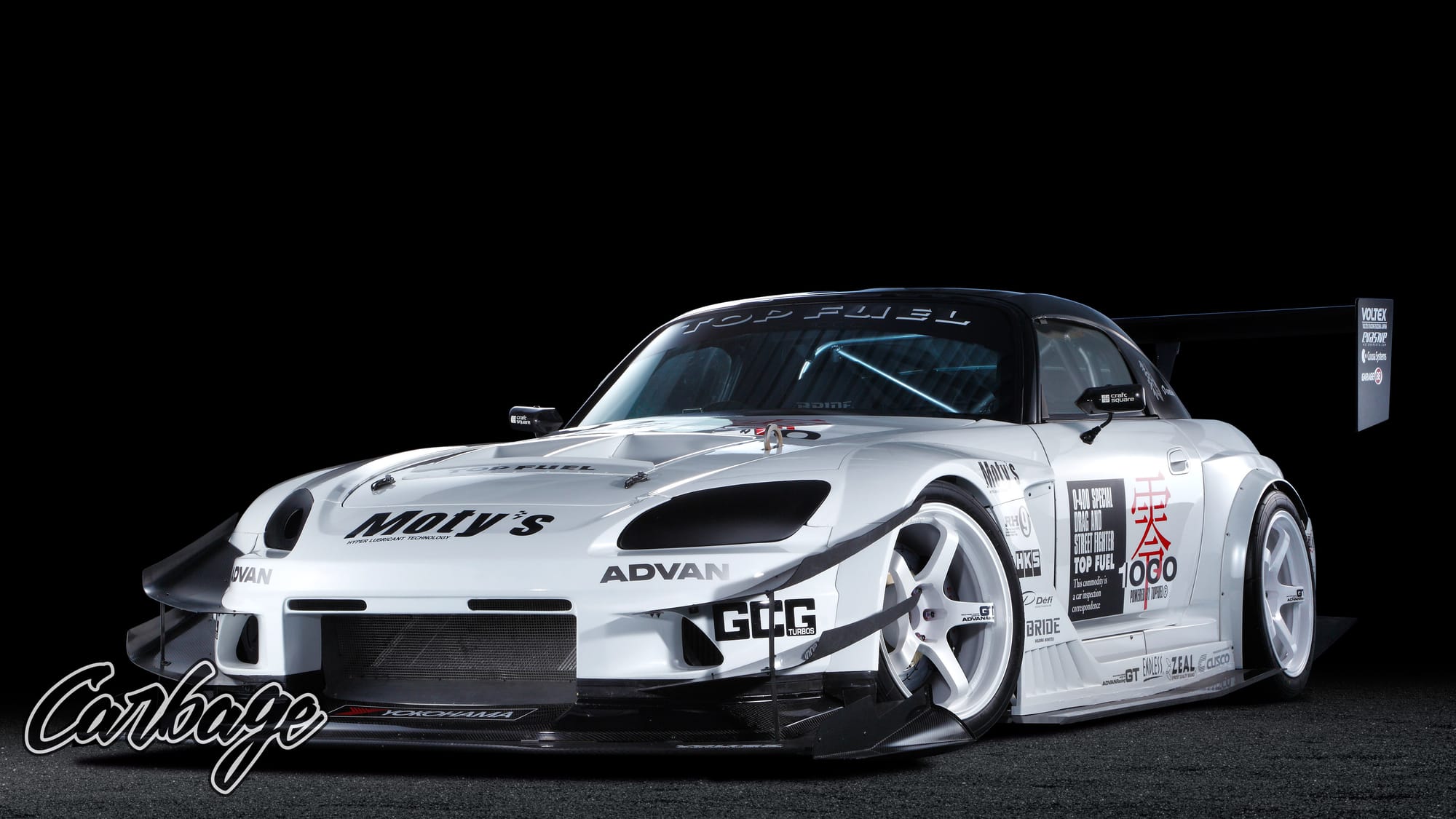

Again, it doesn’t matter what vehicle you drive from a slammed-out drift car to a jacked-up off-roading pickup to a daily driving SUV, alloy wheels are a great item for them all. They can improve a vehicles look, reduce its mass, or can even do both at the same time. When you see “alloy wheels” on the window sticker or description of your next car, don’t fear them. You’re getting something good for your new daily ride.

Comments ()